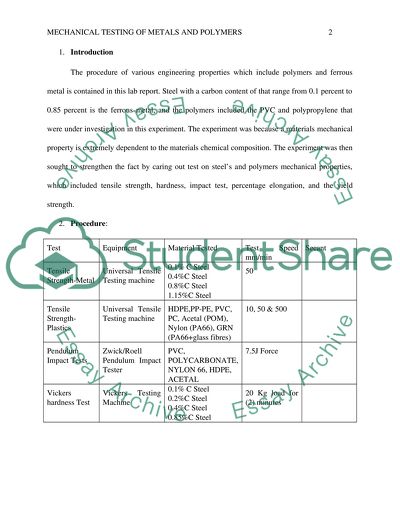

Mechanical testing of metals and polymers Assignment - 1. Retrieved from https://studentshare.org/engineering-and-construction/1465173-mechanical-testing-of-metals-and-polymers

Mechanical Testing of Metals and Polymers Assignment - 1. https://studentshare.org/engineering-and-construction/1465173-mechanical-testing-of-metals-and-polymers.