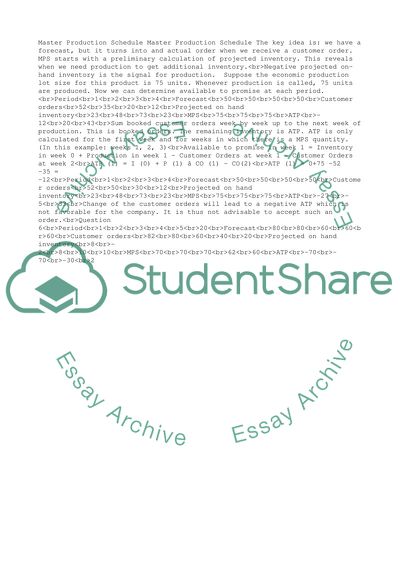

Master Production Schedule Assignment Example | Topics and Well Written Essays - 500 words. Retrieved from https://studentshare.org/management/1688085-operation-management

Master Production Schedule Assignment Example | Topics and Well Written Essays - 500 Words. https://studentshare.org/management/1688085-operation-management.